Lobe pumps are a widely used technology in various industries due to their reliable and efficient performance in pumping difficult-to-handle fluids. They operate using a pair of rotating lobes that create suction and displacement within the pump chamber, offering a unique advantage over other types of pumps. Understanding how lobe pumps function, as well as their benefits, can help improve system performance across multiple sectors. This article explores the critical ways in which lobe pumps contribute to better system performance, focusing on their operational efficiency, versatility, and ability to handle complex fluids.

Enhanced Efficiency in Fluid Handling

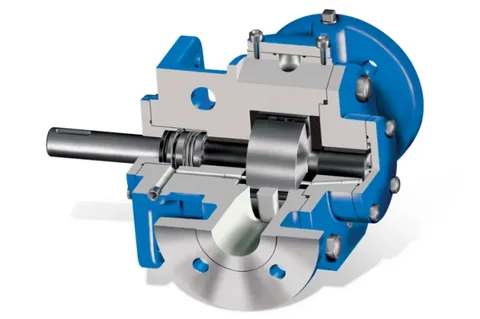

Lobe pumps are designed to handle a wide range of fluids, including those with high viscosity, slurries, and shear-sensitive liquids. The structure of the pump, with its rotating lobes, ensures that the fluid is gently transported without agitation. This method of operation significantly reduces the chances of damaging the product being pumped, which is especially crucial in industries like food processing or pharmaceuticals where preserving the integrity of the product is essential.

Moreover, the design of lobe pumps ensures minimal wear and tear on internal components. Their ability to operate at lower speeds compared to other pump types helps in reducing energy consumption. Since lobe pumps are often employed in applications that involve thick or viscous liquids, their efficiency in such environments translates to fewer operational issues, reduced downtime, and a lower overall cost of maintenance.

Versatility in Applications

The versatility of lobe pumps is one of the key factors that enhance system performance. These pumps can be customized to meet specific requirements, making them suitable for a broad range of applications, from food and beverage processing to chemical manufacturing. The ability to pump fluids with varying viscosities, including both thin and thick substances, makes them indispensable in systems where fluid characteristics may change over time.

Additionally, lobe pumps can handle fluids that contain solids or abrasives, which makes them particularly useful in industries like wastewater treatment or mining. They can also manage products with particulates, ensuring consistent flow without clogging or excessive wear. The adaptability of lobe pumps allows for seamless integration into existing systems, improving overall process efficiency by accommodating changing needs.

Precise Flow Control for Critical Processes

In many industrial applications, precise flow control is crucial to achieving optimal performance. Lobe pumps offer a high degree of accuracy in fluid flow, which is essential in processes where specific amounts of fluid need to be moved at controlled rates. This is particularly important in sectors like pharmaceuticals, where exact formulations and dosages are required for production.

With their ability to provide constant, pulse-free flow, lobe pumps ensure that operations remain stable, without fluctuations that could affect product quality. Furthermore, their ability to maintain a consistent flow rate even under varying pressures helps to optimize production schedules and avoid unnecessary stoppages. This precision is a significant advantage over other pump types that may struggle to maintain a uniform flow.

Low Maintenance and Longevity

Lobe pumps are renowned for their durability and long service life, which is a crucial factor in improving system performance. The simple yet effective design of these pumps means that they require minimal maintenance, reducing the need for frequent repairs or replacements. Their construction typically includes robust materials designed to withstand the wear and tear of continuous operation, which is especially important in high-demand systems.

The longevity of lobe pumps is further enhanced by the fact that they operate with relatively few moving parts, minimizing the chances of mechanical failure. With proper maintenance, such as routine inspection and lubrication, these pumps can provide consistent performance for years, contributing to higher operational uptime and reducing overall maintenance costs. This reliable performance in the long run makes lobe pumps a cost-effective choice for many businesses.

Improved Sanitation and Safety Standards

In industries that require high levels of hygiene, such as food, beverage, and pharmaceuticals, sanitation is a top priority. Lobe pumps are designed to be easy to clean and maintain, which is crucial for ensuring that the systems they are part of meet stringent safety standards. The smooth, non-porous surfaces of the pump housing prevent the accumulation of contaminants, which helps maintain a clean environment and prevents cross-contamination of products.

The sanitary design of lobe pumps also makes them compliant with international safety and quality regulations, such as those set by the FDA or EHEDG. In addition, lobe pumps are often designed with features like quick disassembly or CIP (Clean-In-Place) capabilities, allowing for efficient cleaning without disassembling the pump. This helps companies maintain high standards of hygiene while also improving the overall performance of their systems by preventing contamination.

Conclusion

Lobe pumps offer significant benefits in improving the performance of fluid handling systems. From enhanced efficiency and versatility to precise flow control and low maintenance, these pumps have become integral to numerous industries worldwide. Their ability to handle a wide variety of fluids, maintain consistent flow, and provide reliable performance over long periods makes them a valuable asset for companies aiming to optimize their operations. Whether for food processing, chemical manufacturing, or wastewater treatment, lobe pumps are essential tools that drive system efficiency and contribute to higher product quality, lower operational costs, and improved overall performance.