How Ametek Factory Automation is Enhancing Industrial Efficiency

Introduction

In today’s fast-paced industrial landscape, efficiency is a critical factor that determines a company’s ability to stay competitive and profitable. Ametek Factory Automation, a leader in the automation industry, is at the forefront of providing solutions that significantly enhance industrial efficiency. By leveraging advanced technologies such as precision sensors, automation systems, and real-time data analytics, Ametek is helping manufacturers optimize their operations, reduce waste, and improve overall productivity. This essay explores how Ametek Factory Automation is driving efficiency across various industrial sectors.

Outline

- Introduction

- Company Overview: Ametek Factory Automation

- Company background and mission

- Commitment to enhancing industrial efficiency

- Overview of core efficiency-focused solutions

- Advanced Sensor Technologies for Precision and Control

- Real-time monitoring for process optimization

- Enhancing quality control with precision measurement

- Integration with automation systems for improved efficiency

- Case studies: Efficiency gains through Ametek sensors

- Comprehensive Automation Systems

- Streamlining production processes with automation

- Reducing manual intervention and human error

- Customizable automation solutions for industry-specific needs

- Innovations in automation technology by Ametek

- Industrial Internet of Things (IIoT) and Connectivity

- Enabling smart manufacturing with IIoT integration

- Real-time data collection and decision-making

- Optimizing maintenance and reducing downtime

- Case studies: IIoT-driven efficiency improvements

- Data-Driven Decision Making

- Leveraging data analytics for process optimization

- Predictive maintenance and equipment reliability

- Enhancing operational visibility and control

- Case studies: Data-driven efficiency improvements

- Sustainability and Resource Optimization

- Energy-efficient automation systems

- Reducing waste through precision and control

- Supporting sustainable industrial practices

- Case studies: Sustainability and efficiency in harmony

- Customized Solutions for Diverse Industries

- Automotive: Enhancing production speed and accuracy

- Electronics: Precision manufacturing for complex components

- Food and Beverage: Ensuring safety and efficiency in production

- Pharmaceuticals: Compliance and efficiency in drug manufacturing

- Challenges and Solutions in Implementing Efficiency-Enhancing Technologies

- Overcoming integration challenges with legacy systems

- Ensuring data security and operational continuity

- Balancing cost with long-term efficiency gains

- Tailoring solutions to meet specific industry demands

- Conclusion

- FAQs

Company Overview: Ametek Factory Automation

Company Background and Mission

Ametek Factory Automation, a division of Ametek Inc., is a global leader in providing advanced automation solutions designed to enhance industrial efficiency. The company’s mission is to empower manufacturers with innovative technologies that optimize production processes, improve product quality, and reduce operational costs. With a strong emphasis on research and development, Ametek Factory Automation is dedicated to driving efficiency across various industrial sectors.

Commitment to Enhancing Industrial Efficiency

Ametek Factory Automation is committed to helping manufacturers achieve higher levels of efficiency through the integration of cutting-edge technologies. By focusing on precision, automation, and data-driven decision-making, the company provides solutions that streamline production processes, reduce waste, and improve overall productivity. This commitment to efficiency is reflected in the company’s product offerings and customer-centric approach.

Overview of Core Efficiency-Focused Solutions

Ametek Factory Automation offers a comprehensive range of solutions aimed at enhancing industrial efficiency. These include advanced sensors for precision measurement and control, comprehensive automation systems, IIoT and connectivity solutions, and data analytics tools. By providing these technologies, Ametek helps manufacturers optimize their operations, reduce downtime, and achieve greater efficiency.

Advanced Sensor Technologies for Precision and Control

Real-Time Monitoring for Process Optimization

One of the key ways Ametek Factory Automation enhances industrial efficiency is through its advanced sensor technologies. These sensors provide real-time monitoring of critical process parameters, enabling manufacturers to optimize their operations continuously. By collecting and analyzing data in real-time, Ametek’s sensors help manufacturers identify inefficiencies, adjust processes, and maintain optimal production conditions.

Enhancing Quality Control with Precision Measurement

Precision measurement is essential for maintaining high standards of quality control in manufacturing. Ametek’s sensors are designed to provide accurate, reliable measurements of key variables such as temperature, pressure, and displacement. By ensuring that products meet exact specifications, these sensors help manufacturers reduce defects, minimize rework, and improve overall product quality, all of which contribute to greater efficiency.

Integration with Automation Systems for Improved Efficiency

Ametek’s sensors are designed to integrate seamlessly with automation systems, providing real-time data that can be used to control and optimize manufacturing processes. This integration allows for automated adjustments to be made in real-time, ensuring that production remains within optimal parameters. By reducing manual intervention and enabling more precise control, Ametek’s sensor technologies contribute to significant efficiency gains in manufacturing.

Case Studies: Efficiency Gains Through Ametek Sensors

Ametek Factory Automation’s sensors have been successfully implemented across various industries, leading to measurable efficiency gains. For example, in the automotive industry, Ametek’s displacement sensors have been used to ensure the precision of assembly processes, resulting in faster production times and reduced waste. In the electronics sector, temperature and pressure sensors have helped manufacturers maintain tight control over production environments, leading to higher yields and reduced downtime. These case studies highlight the impact of Ametek’s sensor technologies on enhancing industrial efficiency.

Comprehensive Automation Systems

Streamlining Production Processes with Automation

Ametek Factory Automation offers comprehensive automation systems designed to streamline production processes and reduce the need for manual intervention. By automating repetitive tasks and complex operations, these systems help manufacturers increase throughput, reduce variability, and improve overall efficiency. Ametek’s automation solutions are equipped with advanced control capabilities that enable precise management of production processes, ensuring that operations run smoothly and efficiently.

Reducing Manual Intervention and Human Error

Automation plays a critical role in reducing human error and improving consistency in manufacturing processes. Ametek’s automation systems are designed to minimize the need for manual intervention, reducing the risk of errors and ensuring that production remains consistent and reliable. By automating key processes, manufacturers can achieve higher levels of efficiency and maintain consistent product quality.

Customizable Automation Solutions for Industry-Specific Needs

Ametek Factory Automation provides customizable automation solutions that are tailored to meet the specific needs of different industries. Whether it’s a high-speed assembly line in the automotive sector or a precision coating process in electronics manufacturing, Ametek’s solutions can be adapted to optimize performance and efficiency. This flexibility allows manufacturers to achieve their production goals while maintaining the highest standards of quality and safety.

Innovations in Automation Technology by Ametek

Ametek Factory Automation is continually innovating in the field of automation technology. The company’s latest developments include advanced automation systems that incorporate machine learning and AI to improve decision-making and process optimization. These innovations are designed to help manufacturers stay ahead of the curve in an increasingly competitive market by providing them with the tools they need to achieve operational excellence.

Industrial Internet of Things (IIoT) and Connectivity

Enabling Smart Manufacturing with IIoT Integration

The Industrial Internet of Things (IIoT) is a cornerstone of smart manufacturing, and Ametek Factory Automation offers a range of IIoT solutions that enable manufacturers to connect machines, systems, and devices across the factory floor. This connectivity allows for real-time data collection, monitoring, and analysis, providing manufacturers with the insights they need to optimize production processes and improve efficiency. Ametek’s IIoT solutions are designed to support the transition to smart manufacturing, where data-driven decision-making is key to maintaining competitiveness.

Real-Time Data Collection and Decision-Making

Real-time data collection is essential for maintaining efficiency in modern manufacturing environments. Ametek’s IIoT solutions enable manufacturers to collect and analyze data from sensors, machines, and systems in real-time, providing immediate feedback on production conditions and performance. This real-time data allows manufacturers to make informed decisions quickly, reducing downtime, preventing issues before they impact production, and optimizing processes for greater efficiency.

Optimizing Maintenance and Reducing Downtime

One of the key benefits of IIoT integration is the ability to optimize maintenance processes and reduce downtime. Ametek’s IIoT solutions enable predictive maintenance by monitoring the condition of equipment in real-time and identifying potential issues before they lead to failure. By performing maintenance proactively, manufacturers can extend the lifespan of their equipment, reduce unplanned downtime, and maintain consistent production levels.

Case Studies: IIoT-Driven Efficiency Improvements

Ametek Factory Automation has implemented IIoT-driven solutions in various industries, leading to significant improvements in efficiency. For example, in the aerospace industry, Ametek’s IIoT solutions have been used to monitor the condition of critical components in real-time, enabling predictive maintenance and reducing the risk of failure. In the automotive sector, IIoT integration has helped optimize assembly line operations, resulting in faster production times and higher quality outcomes. These case studies demonstrate the impact of IIoT on enhancing industrial efficiency.

Data-Driven Decision Making

Leveraging Data Analytics for Process Optimization

Data analytics is a powerful tool for optimizing manufacturing processes, and Ametek Factory Automation’s solutions are designed to help manufacturers leverage data to improve efficiency. By collecting and analyzing data from across the production environment, Ametek’s data analytics tools provide manufacturers with the insights they need to identify inefficiencies, optimize processes, and make informed decisions that enhance productivity.

Predictive Maintenance and Equipment Reliability

Predictive maintenance is a key application of data analytics in manufacturing, and Ametek’s solutions are designed to support this approach. By analyzing data from sensors and machines, manufacturers can predict when equipment is likely to fail and perform maintenance before a breakdown occurs. This proactive approach reduces downtime, extends the lifespan of machinery, and improves overall equipment reliability, contributing to greater efficiency.

Enhancing Operational Visibility and Control

Operational visibility is essential for maintaining efficiency, and Ametek’s data analytics solutions provide manufacturers with real-time insights into their operations. By monitoring key performance indicators (KPIs) and tracking production metrics, manufacturers can gain a comprehensive view of their operations, identify areas for improvement, and implement changes that enhance efficiency. This data-driven approach to manufacturing helps manufacturers stay agile and responsive to changing market conditions.

Case Studies: Data-Driven Efficiency Improvements

Ametek Factory Automation has successfully implemented data-driven decision-making solutions in various industries, leading to measurable improvements in efficiency. For example, in the electronics sector, data analytics has been used to optimize production processes, resulting in higher yields and reduced waste. In the automotive industry, predictive maintenance powered by data analytics has helped reduce downtime and improve equipment reliability. These case studies highlight the impact of data-driven decision-making on enhancing industrial efficiency.

Sustainability and Resource Optimization

Energy-Efficient Automation Systems

Sustainability is a key focus for Ametek Factory Automation, and the company offers a range of energy-efficient automation systems designed to reduce energy consumption while maintaining high levels of productivity. By optimizing energy use across the production floor, these systems help manufacturers reduce operating costs and minimize their environmental impact. Ametek’s commitment to sustainability is reflected in its product development and service delivery, ensuring that manufacturers can achieve their efficiency goals in an environmentally responsible manner.

Reducing Waste Through Precision and Control

Precision and control are essential for reducing waste in manufacturing processes, and Ametek’s automation solutions are designed to provide manufacturers with the tools they need to achieve this. By ensuring that production processes are tightly controlled and optimized, Ametek’s solutions help manufacturers minimize material waste, reduce defects, and improve overall resource efficiency. This not only supports sustainability goals but also contributes to cost savings and improved profitability.

Supporting Sustainable Industrial Practices

Ametek Factory Automation is committed to supporting sustainable industrial practices through its innovative technologies and solutions. The company works closely with its clients to develop customized solutions that align with their sustainability objectives, whether it’s reducing energy consumption, minimizing waste, or optimizing resource use. Ametek’s commitment to sustainability is reflected in its product development, service delivery, and corporate responsibility initiatives.

Case Studies: Sustainability and Efficiency in Harmony

In the electronics sector, precision automation has helped manufacturers minimize waste and improve resource efficiency. These case studies demonstrate the positive impact of Ametek’s solutions on promoting sustainability and efficiency in manufacturing.

Customized Solutions for Diverse Industries

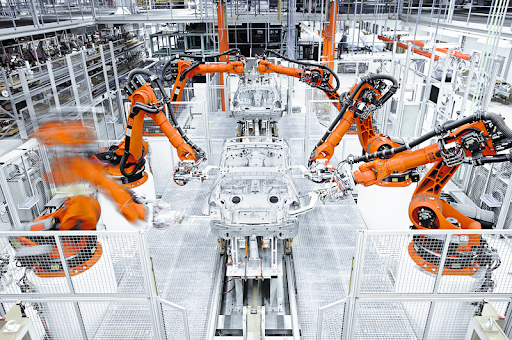

Automotive: Enhancing Production Speed and Accuracy

Ametek Factory Automation offers specialized solutions for the automotive industry, where speed and accuracy are critical. From advanced sensors and measurement systems to comprehensive automation solutions, Ametek’s technologies help automotive manufacturers optimize their production processes, improve product quality, and reduce costs. Whether it’s ensuring the accuracy of assembly processes or enhancing the efficiency of engine manufacturing, Ametek’s solutions are designed to meet the unique needs of the automotive sector.

Electronics: Precision Manufacturing for Complex Components

In the electronics industry, where precision and speed are paramount, Ametek Factory Automation provides solutions that ensure high-quality production at scale. Ametek’s sensors and automation systems are used to monitor and control critical processes, ensuring that electronic components are manufactured to exacting standards. These solutions enable electronics manufacturers to meet tight production schedules while maintaining strict quality standards, leading to greater overall efficiency.

Food and Beverage: Ensuring Safety and Efficiency in Production

The food and beverage industry faces unique challenges related to quality control and regulatory compliance. Ametek Factory Automation’s solutions address these challenges by providing precision sensors, automation systems, and safety technologies that ensure products meet safety standards while optimizing production efficiency. By enhancing both safety and efficiency, these solutions help food and beverage manufacturers stay competitive in a demanding market.

Pharmaceuticals: Compliance and Efficiency in Drug Manufacturing

In the pharmaceutical industry, where precision, quality, and compliance are paramount, Ametek Factory Automation offers tailored solutions that meet the industry’s stringent requirements. These solutions include AI-powered predictive maintenance, automated inspection systems, and real-time environmental monitoring tools that ensure consistent product quality and adherence to regulatory standards. By automating critical processes, Ametek helps pharmaceutical manufacturers maintain efficiency while ensuring compliance.

Challenges and Solutions in Implementing Efficiency-Enhancing Technologies

Overcoming Integration Challenges with Legacy Systems

Integrating new technologies into existing manufacturing systems can be challenging, especially when dealing with legacy infrastructure. Ametek Factory Automation works closely with its clients to develop tailored integration strategies that minimize disruption and ensure a smooth transition to modern manufacturing technologies. This collaborative approach helps manufacturers overcome the technical and logistical challenges of implementing new solutions.

Ensuring Data Security and Operational Continuity

As manufacturing becomes increasingly data-driven, ensuring data security and operational continuity is critical. Ametek Factory Automation prioritizes data security in all its solutions, implementing robust cybersecurity measures to protect sensitive information and ensure the integrity of manufacturing operations. By addressing data security challenges proactively, manufacturers can maintain trust and confidence in their automated systems.

Balancing Cost with Long-Term Efficiency Gains

Ametek Factory Automation works with its clients to develop cost-effective strategies that deliver measurable efficiency gains and long-term benefits. By focusing on scalable, flexible solutions, the company helps manufacturers achieve their efficiency goals without overextending their budgets.

Tailoring Solutions to Meet Specific Industry Demands

Every industry has unique challenges and requirements, and Ametek Factory Automation is committed to providing customized solutions that address these specific needs.

Conclusion

Ametek Factory Automation is enhancing industrial efficiency through its innovative technologies and solutions. By providing advanced sensors, comprehensive automation systems, IIoT integration, and data analytics tools, Ametek helps manufacturers optimize their operations, reduce waste, and improve overall productivity. As the industrial landscape continues to evolve, Ametek remains committed to driving efficiency and operational excellence, ensuring that its clients have the tools they need to succeed in a competitive market.

FAQs

- How does Ametek Factory Automation enhance industrial efficiency?

- Answer: Ametek enhances industrial efficiency by providing advanced sensors, automation systems.

- What role do Ametek’s sensors play in improving manufacturing efficiency?

- Answer: Ametek’s sensors provide real-time monitoring and precision measurement of critical process parameters, enabling manufacturers to optimize operations, reduce defects, and improve product quality, all of which contribute to greater efficiency.

- How does Ametek support smart manufacturing?

- Answer: Ametek supports smart manufacturing by offering IIoT solutions that enable real-time data collection, predictive maintenance, and data-driven decision-making, helping manufacturers optimize their operations and improve efficiency.

- What industries benefit from Ametek Factory Automation’s efficiency-enhancing solutions?

- Answer: Ametek provides efficiency-enhancing solutions for a wide range of industries, including automotive, electronics, food and beverage, and pharmaceuticals, each tailored to meet the specific needs and challenges of these sectors.

- How does Ametek address the challenges of integrating new technologies into existing systems?

- Answer: Ametek addresses integration challenges by working closely with clients to develop tailored strategies that minimize disruption and ensure a smooth transition to modern manufacturing technologies, while also prioritizing data security and operational continuity.